Packaging Bee: Where Style Meets Versatility in Sleeve Packaging!

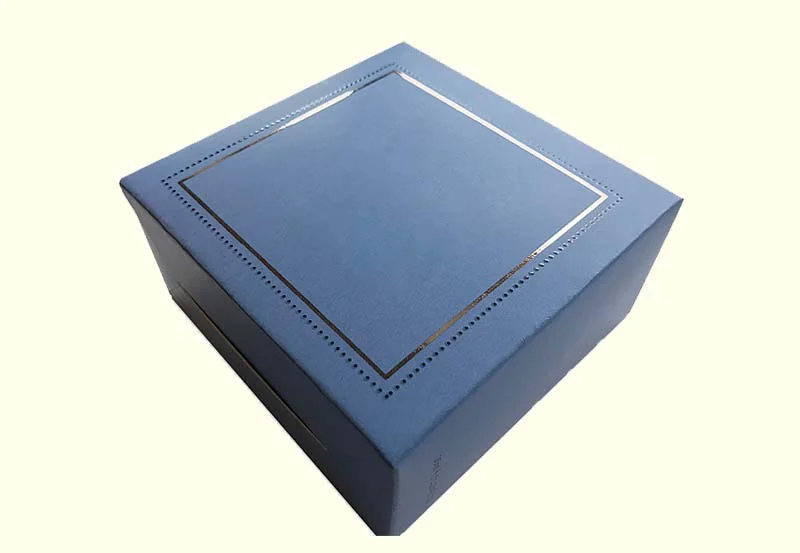

Sleeve packaging tops the list of packaging that offers both style, practicality as well as a touch of customisation. At Packaging Bee, we have a wide range of packaging sleeves services that capture the persona of your brand. If you require box sleeve packaging for a new release or luxury sleeves packaging for a premium item, we provide packaging that makes a statement.

Our packaging sleeves represent the versatility, advantages, and possibilities of sleeves for packaging and how you, businesses across Australia, can benefit from working with Packaging Bee. Order now!

What Is Sleeve Packaging?

Sleeve packaging is a stylish and flexible kind of packaging. It usually fits over a box, container or a product. There are several features of ad words, and all in all it is like a cover over your product which gives it an additional glamour. Perfect for food and beverages companies and other industries involved in the production of cosmetics and retail companies, these sleeves represent a modern approach to improving the product's appearance.

Key Features of Sleeve Packaging

- Versatility: Ideal for using on boxes, bottles, jars and other shapes.

- Ease of Use: Simple to apply and remove.

- Customisable: It comes in varieties, in terms of size, material and design.

- Cost-Effective: This is a budget-friendly packaging solution.

Why Choose Packaging Bee for Your Sleeves Packaging Needs?

At Packaging bee AU, we know the power that was embodied in packaging that creates an initial impression of the products. The packaging sleeves Australia are also to contain your product and at the same time guarantee a consumer’s attention.

Unique Benefits of Our Packaging Sleeves:

The following are the benefits of using these sleeves:

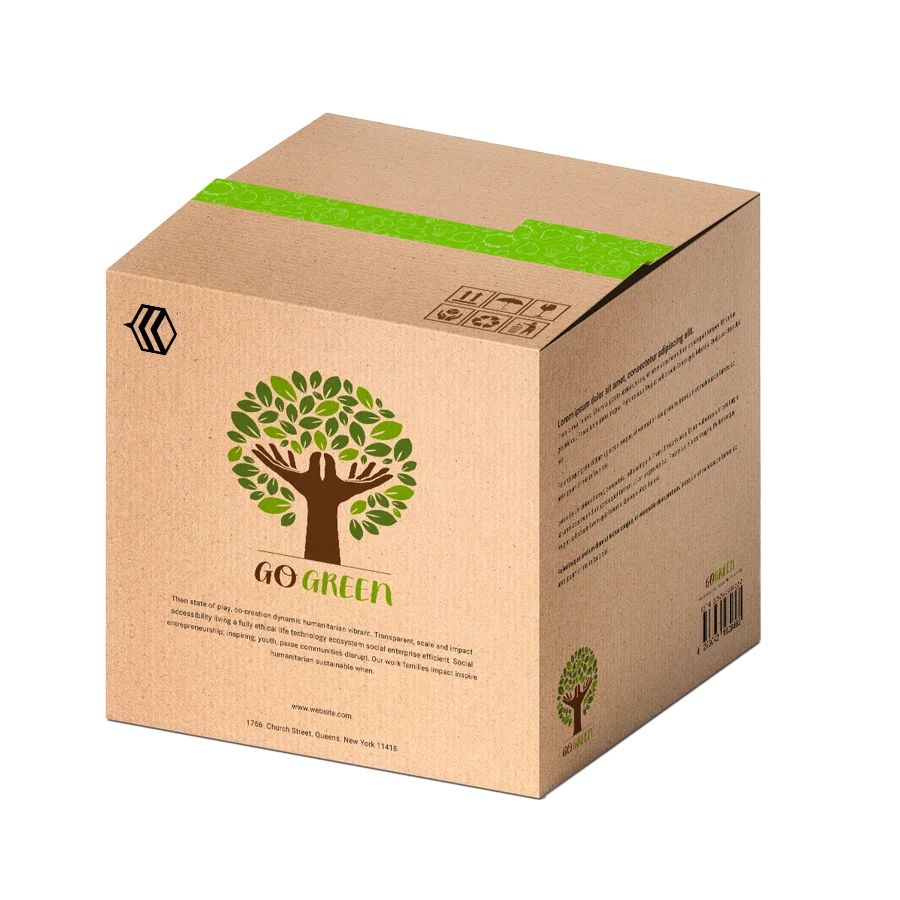

Eco-Friendly Options

With respect to the environmental aspect, sustainable solutions are inherent to all of our solutions. To keep it green, pick between recyclable and biodegradable materials, including paper sleeve and carton sleeve packaging.

Exceptional Customisation

This is true for both custom printed packaging for sleeves as well as clear sleeve packaging. We make your vision come to reality. Add logos, vivid colour and creatively designed patterns to express your company's personality.

Durability and Quality

Our packaging sleeves are designed to last throughout the handling process in addition to the temptation to look.

Affordable Luxury

Searching for ways to achieve a luxury atmosphere without spending too much money? With every packaging sleeve, we provide an elegant edge at mass market pricing.

Quick Turnaround

Tight deadline? No problem! We are committed to delivering across Australia in a short time as per the demands of business.

Applications of Sleeve Packaging

There are multiple uses of packaging sleeves. Some of them are the following:

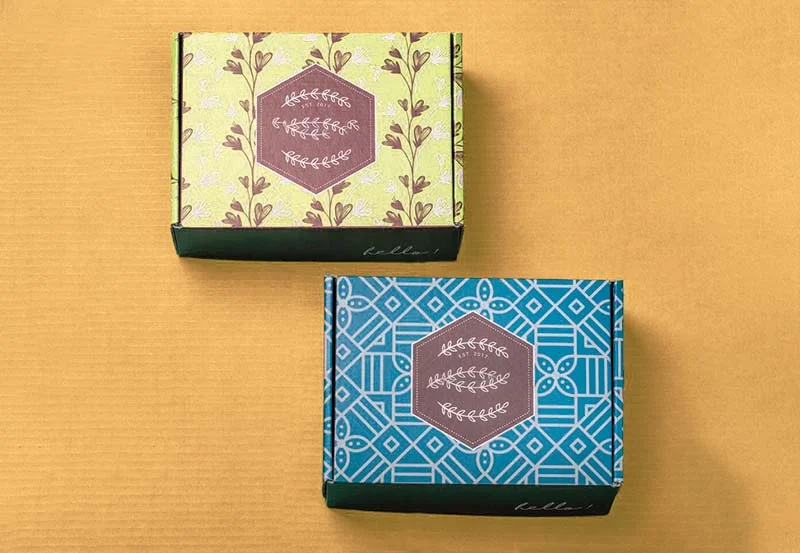

1. Retail Products

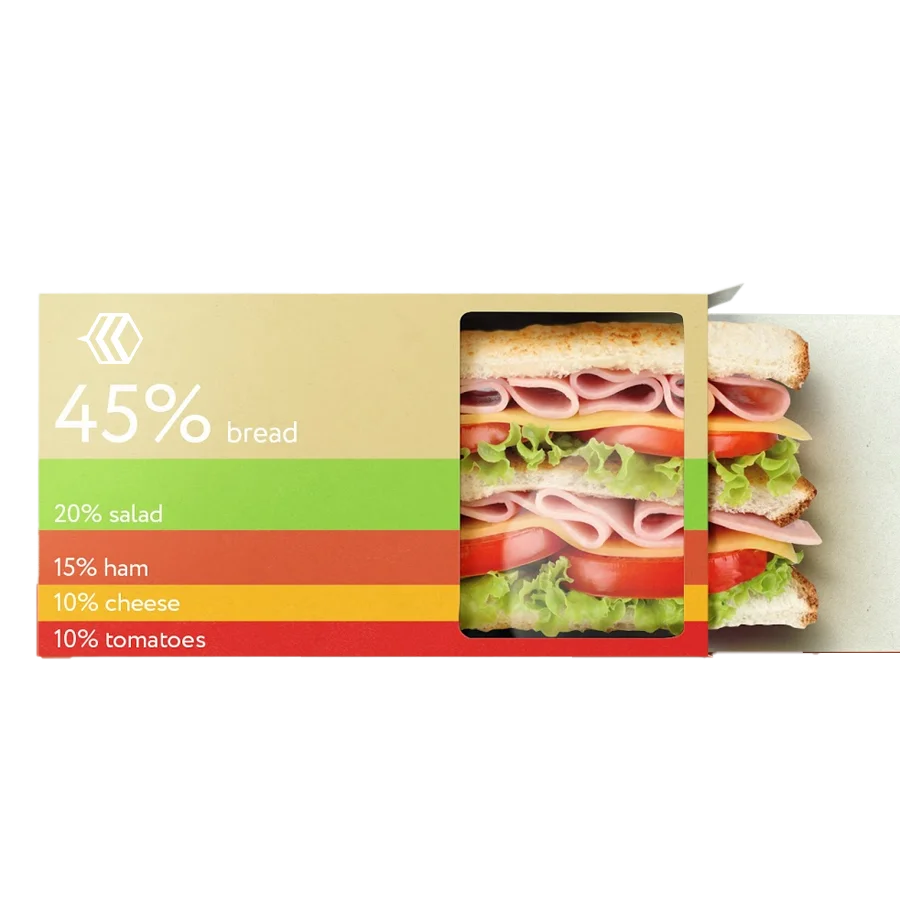

There is tough competition in the retail business and the first impressions are indicative of success. The packaging box sleeves design enables you to bring an aesthetic appeal that will cause consumers to develop an urge to acquire the packaged product. Packaging sleeves in custom print to specific product features or advertising slogans.

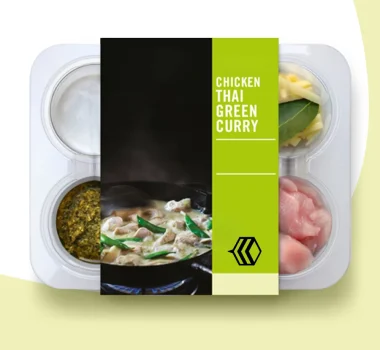

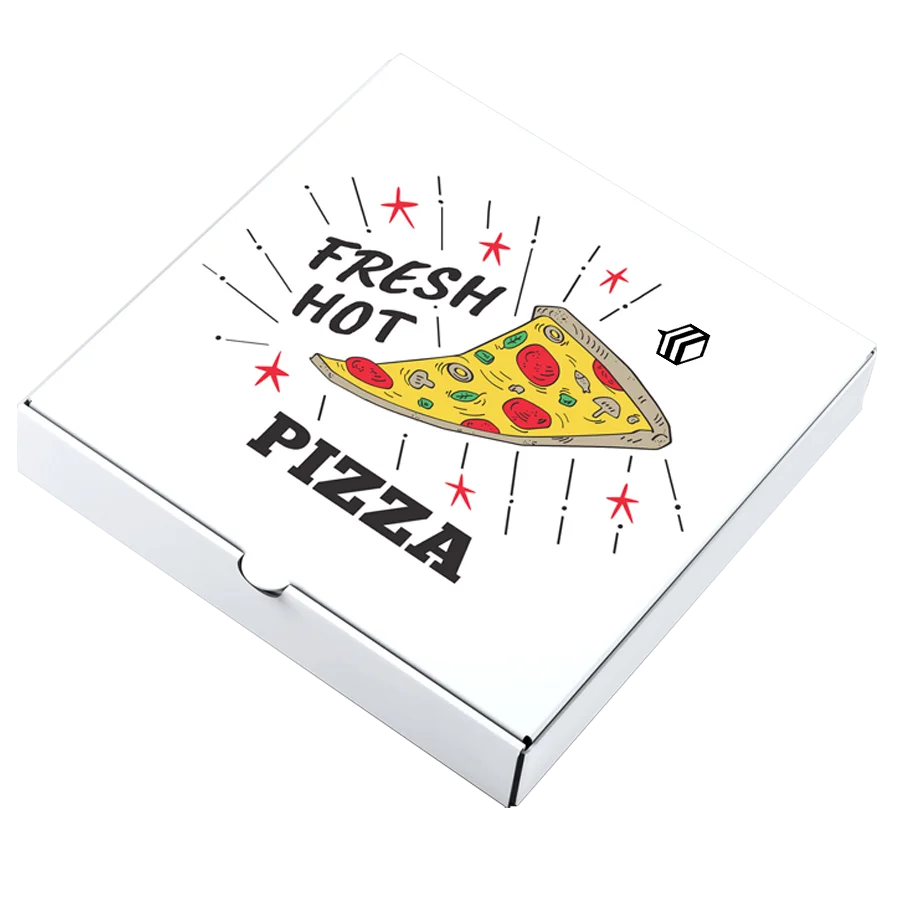

2. Food and Beverage Industry

One good example is chocolates, pastries or frozen meals, the carton packaging sleeve is just the right package sleeve as it serves the functionality and the aesthetic value. Divide the nutritional information or the branding to the sleeve to give it a professional look.

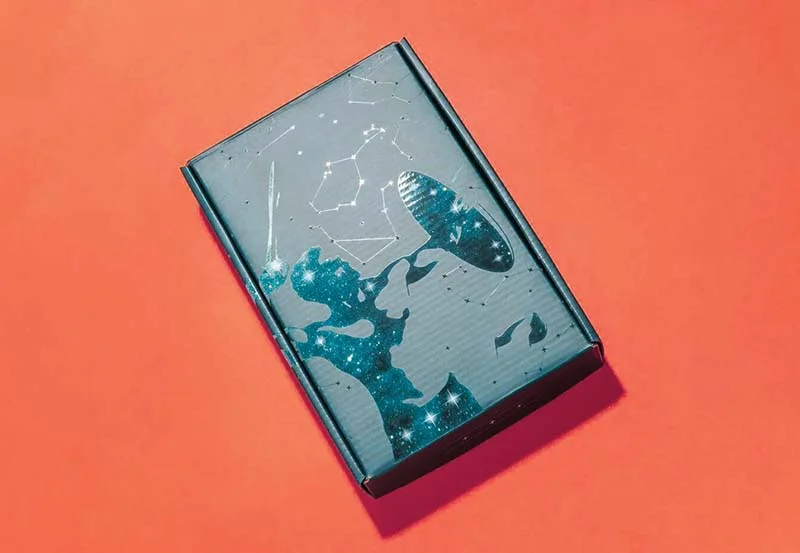

3. E-Commerce Packaging

Online businesses must capture the customers from day one, right from the time they open their package. An added layer when it comes to packaging, particularly the sleeve, gives the customer a more memorable experience, while making him or her remain loyal to the product.

4. Seasonal Promotions

Package your gifts and products in print sleeve packaging to enhance celebrations of events such as holidays and occasions. Offer seasonal products with details to make customers feel that they have to purchase the product before it is out of stock.

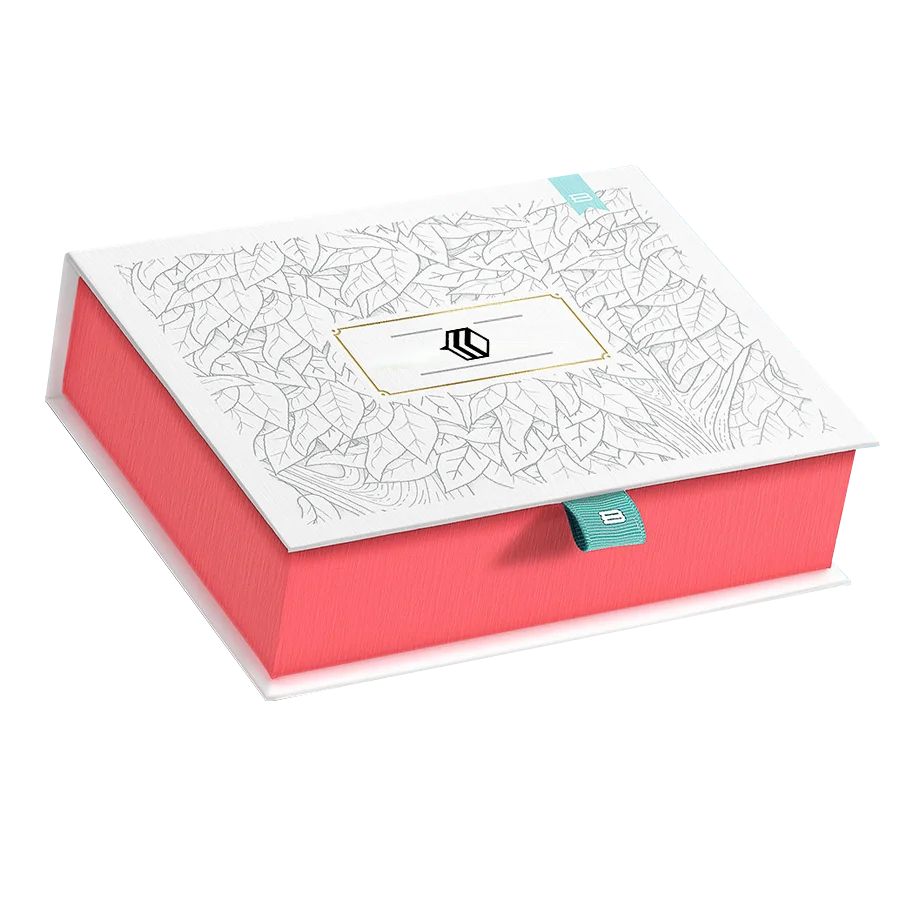

5. Cosmetics and Luxury Items

Packed perfumes, skincare products and many other products look way elegant with brilliant box packaging sleeves. Select luxury sleeves packaging as an ideal accessory to such products in order to give added value.

Customisation Options That Bring Your Vision to Life

That is why with Packaging Bee, there are countless opportunities to choose from. Our customisation services allow you to tailor every aspect of your packaging box sleeve design:

- Materials: Choose between plain paper, thick cardboard or clear plastic for clear sleeves packaging materials.

- Sizes and Shapes: Whether for a standard frame size or a custom size, there is always a solution at our company.

- Personalised Details: For example, it is possible to print QR codes, barcodes or perforations to add extra capability.

Why Sleeve Packaging Is the Smart Choice?

Cost-Efficiency

To the surprise of many, packaging sleeves cost less than full-fledged sleeve packaging boxes and make the same impression. They are best suitable for small businesses or start-ups that want to advance branding without spending much.

Brand Versatility

The versatile Australian packaging sleeves is provided here through custom packaging sleeves Australia to clear packaging sleeve,s and it provide versatility for catering to customer needs.

Eco-Conscious Consumers

As the perception of the environment is becoming a concern, customers start making purchases of eco-friendly products. Using paper sleeve packaging or carton packaging shows that you are environmentally conscious and eco-friendly.

Creating Urgency with Special Offers

From time to time, we have some amazing discounts that you shouldn’t miss out on. Order your custom printed packaging sleeves today and enjoy:

- Discounts on Bulk Orders: You will find that the prices reduce when you order in bulk.

- Free Design Assistance: Our expert will assist you in choosing the right packaging sleeve design for your product.

- Express Shipping Across Australia: Get your order faster than ever.

Enhance Your Packaging Game with Sleeve Packaging

This packaging provides consumers with the attractiveness, affordability, and sustainability they deserve for their products. Welcome to Packaging Bee where getting people to notice your packaging is our winning achievement. For instance, we have box packaging sleeves and luxury packaging sleeves, which cater for the individual needs of companies doing business in Australia.

Buy today and start the journey towards revolutionising your product display. Packaging Bee provides the clients with quality packaging solutions at their fingertips!

Stand Out with Packaging Bee’s Expertise

Our Commitment to Quality

At Packaging Bee, we are convinced that good packaging adds value to every product currently in the market. We incorporate innovation in technology and creativity in order to produce superior work among our team. We have the box packaging sleeve for a product launch advertising need or a custom packaging sleeve for a unique promotion purpose.

Customer-Centric Approach

We contact you from the time of consultation to production in order to create your dream project. Our professional staff is available for consultation to deliver the best information to the clients.

Make Your Sleeves Attractive With Our Colour Models

As observed at this juncture, colour models are very important, especially in printing and packaging of goods to make sure that the designs created get an accurate representation. There are many models in which CMYK, PMS, and Flexography are some popular models widely used in industries, depending on the type of requirement.

CMYK- Cyan, Magenta, Yellow, Key (Black)

CMYK is a subtractive colour model mainly in digital and offset printing. Of course, CMYK produces many colours as it combines the percentages of cyan, magenta, yellow, and black. It is most suitable for projects that need various colours printed on production, like brochures, packing sleeves and posters. However, because of the ink blending used during the printing process, it is nearly impossible to get two sets of prints to have exactly the same shade of ink.

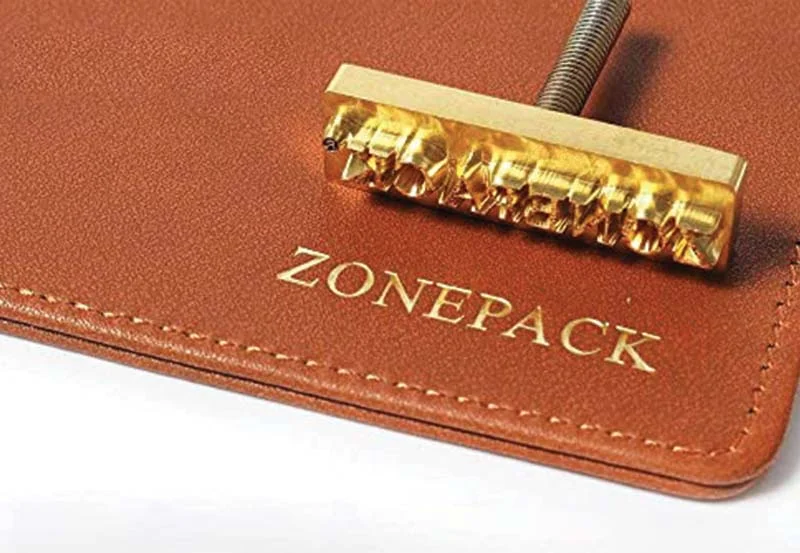

PMS (Pantone Matching System)

The PMS system provides firms with a standard range of individual colours for reproducible colour matching across various print cycles and on various types of materials. It comes in handy in branding, especially in projects involving identity and colour tolerance that is very low, for instance, logo designing as well as product labelling.

PMS colours are frequently combined with CMYK for the projects that need accurate spot colours filled with other colours and pictures.

Flexography

Flexography is an all-purpose printing technique that is chiefly applied to packaging materials. They are also variable because the machine uses flexible packaging sleeve printing plates and can work with various forms of substrates such as paper, plastic and cardboard sleeves. Flexo can execute CMYK as well as PMS. Therefore, it is perfect for higher quantity projects.

Our Printing Techniques

Different techniques of printing are vital for the beauty and functionality of sleeve packaging. Among all the commercial types of printing used for sleeve packaging, the widely embraced techniques include digital, offset, and screen printing.

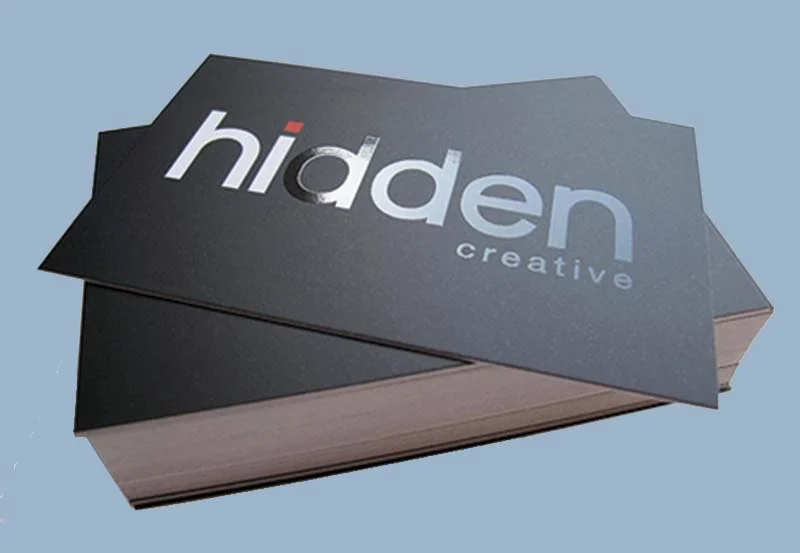

Digital Printing Technique

Digital Printing is the newest and most flexible type, designed for small to mid quantities or of course, for personalised boxes. It employs the use of digital files to actually spray ink right onto the material of the sleeve and the outcome gives a very detailed print.

Yet, this method is rapid, less costly when producing small quantities of parts and permits modification of designs frequently. To be more specific, it is ideal for companies that require certain freedoms in terms of the branding or the packaging of products.

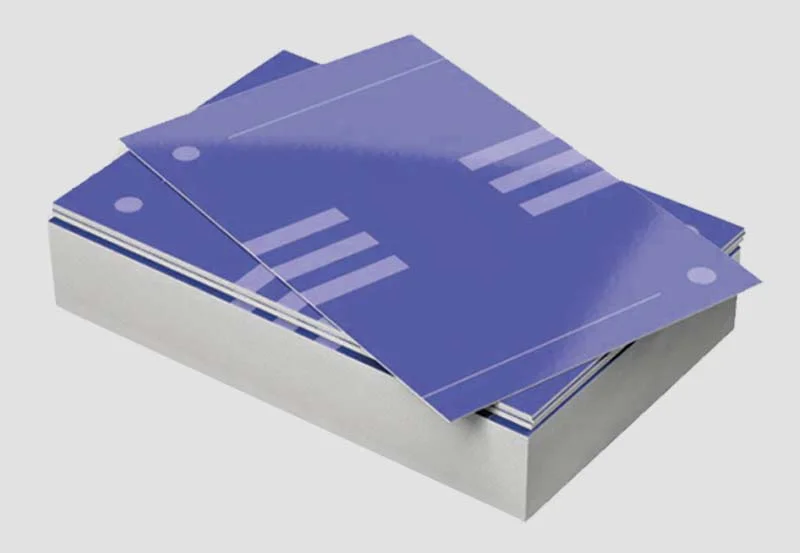

Offset Printing Technique

We also have the Offset Printing, which works best in large runs of sleeve packaging because of the impressive colour integrity. It entails putting the ink on a rubber blanket from a plate, then applying it on the packaging material. This is one of the most efficient techniques with very good results, especially where the design is complicated or there are many colours involved. It is ideal for large orders, and it is significantly cheaper when therefore it is ideal for large orders.

Screen Printing Technique

It is a printing technique in which ink is laid only on the material through a screen. Heavy-duty gives clarity to print bold and solid colours and is widely used for packaging material, which has a touch or feel factor. Compared to the digital or offset printing, it has slightly lower quality for details on fine elements, but it is very much better when it comes to durability, especially when printing in plastic or cloth materials.

Therefore, each type of printing technique varies depending on the required printing results and the quantity in the order, together with the material used in sleeve packaging.

Our Sampling Options

Samples are critical in developing new products and creating packaging designs to communicate what the real product will look like in the market to the firms. There are three main types of samples: 2D, 3D, and physical.

2D Samples

2D Samples are flat images of a design. These samples bear the art work, the colours and the layout of the packaging but do not give the feel of the size, shape or even the tactile sense of the pack. They are useful in a way to provide a fast and easy look at design features. We send these designs to our clients to help them make wise decisions.

Video Mockups

Furthermore, we offer 3D Samples to our clients. These samples give business entities an opportunity to assess how it will appear in the real world from such angles as is provided below in comparison with the 2D samples. They are ideal for use where a true fitting test of the packaging design on its structure is necessary, especially on packaging prototypes.

Physical Samples

Moreover, they are made of the planned raw material. Therefore, they are actual samples of the product. These samples help to provide a realistic means of measuring how the texture, weight and overall ‘feel’ of the design idea is as a practical, as well as being as aesthetically pleasing, product.

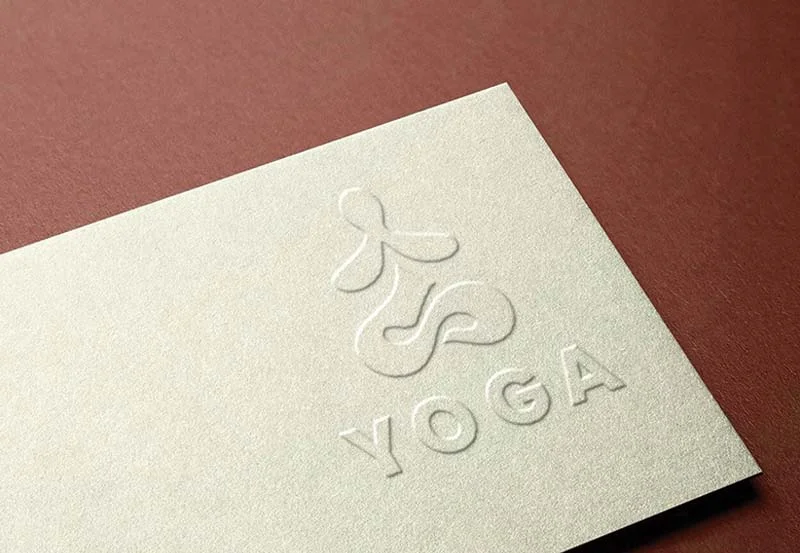

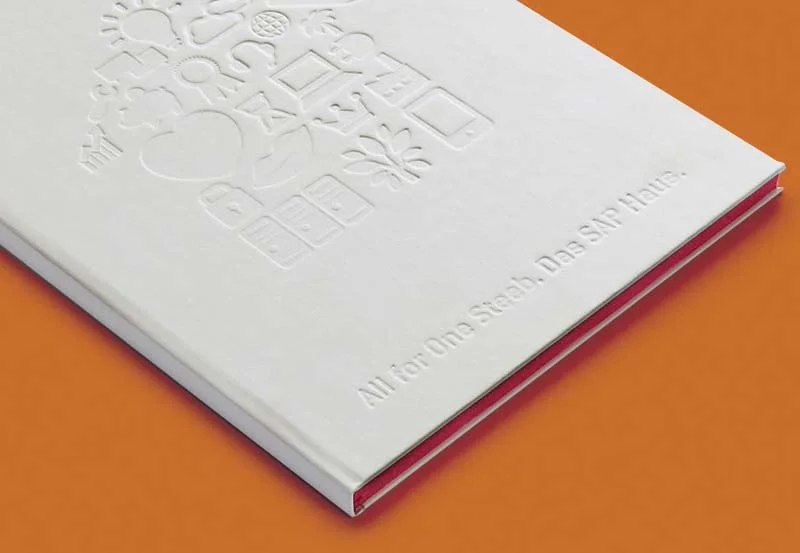

Coatings

Coatings play a vital role in the aesthetic value, durability and performance of the packaging. In packaging, there are different coating methods, and each has its specific use as discussed below.

Gloss Coating

It affords a shiny surface that enables intensity in colours and makes designs and graphic arts to pop. It also gives some measure of protection against grime and dampness as well.

Furthermore, it combines the sleek and smooth touch for the package and provides a non-reflective outer lay to give the packaging a classy look. Though it is not as shiny as the gloss designs, it is best for designs that would like to somehow downplay elegance.

Soft-Touch Coating

It creates sophistication and a silky texture to the Touch packaging. It enhances the feel of the buttons while bringing a luxurious type of touch to the user interface, which makes it ideal for luxury products.

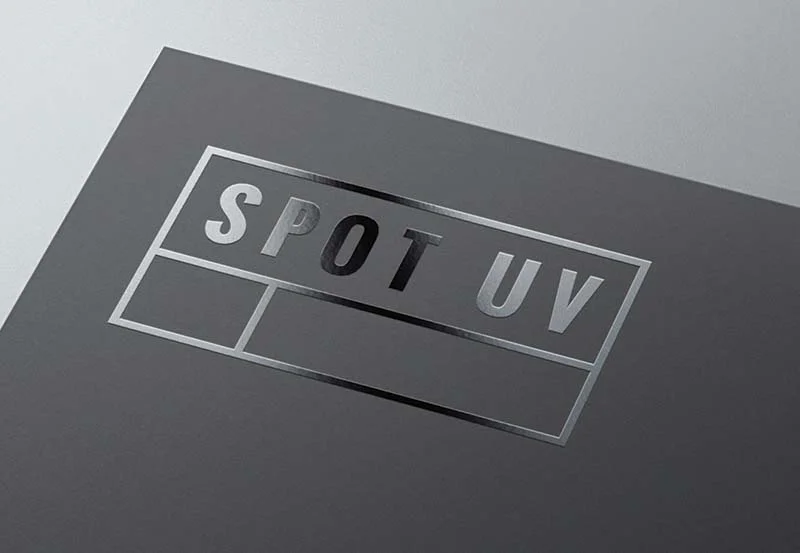

UV Coating

This coating employs UV light to dry the coating, thus making it very resilient to abrasion, colour change and water. This is well suited to the promotion of the durability of packaging material, most of which deteriorate when exposed to handling or light.

Coating types are incorporated for appearance and purpose, with each bringing multiple benefits depending on the product or design requirement.

How to Order Your Custom Sleeve Packaging?

Are you willing to take your product presentation to another level? Ordering with Packaging Bee is simple:

- Get a Quote: Register online with your specifications on the form provided.

- Collaborate on Design: Consult with us to bring an end to your packaging design for sleeves.

- Approve and Produce: Once you approve the design, we shall start the manufacturing process.

- Receive Your Order: Get free shipping within Australia with express delivery.

Why Do Australian Businesses Trust Packaging Bee?

In many years, people have come to know that ours is a reliable organisation that never shies away from innovation. Businesses across Australia choose us for our:

-

- Unmatched Quality: Above all, we create these sleeves in high-quality materials. We ensure that you get the best packaging solutions.

- Affordable Pricing: Our sleeves are affordable than our competitors’. It helps you to manage your business on a limited budget.

- Eco-Friendly Options: Furthermore, we use eco-friendly materials to make these sleeves. It shows your commitment to environmental sustainability when you buy these sleeves.

- Creative Design Solutions: Moreover, our team of designers are expert. You can consult them to get your designs.

- Free Shipping: Free shipping minimises your spending and increases your profit.

Get in touch with us via email at [email protected] or call us at +61290995643.