13

By: Monica Harper

The shipping process is, without doubt, one of the most vital aspects in any product delivery, whether you are operating a physical retail store or running a successful eCommerce business. The choice of shipping cartons and their measuring ranks very high among the different factors that constitute the process. Well-measured cartons will not only shield your merchandise from damage but will also save you money on shipping, improve customer satisfaction, and make your logistics operations more efficient. A comprehensive reference addressing shipping carton dimensions, from accurate measuring of your cartons, understanding dimensions and thicknesses, and a guide to standard carton sizes will be provided here.

Why are shipping carton dimensions important?

The exact dimensions of shipping cartons are vital for several reasons:

Product Protection: Appropriate boxes hold the products in place and hence reduce the incidence of damage during shipment.

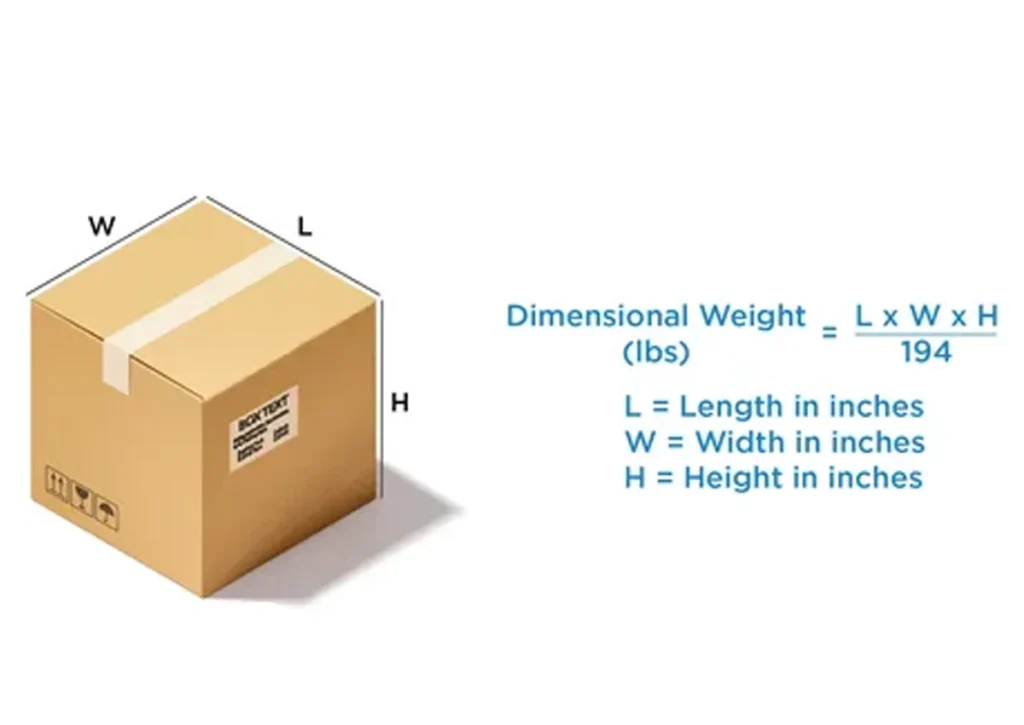

Cost Saving: Choosing the right box size may result in a cost reduction. The prices of shipping are frequently based on dimensional weight.

Customer Satisfaction: Perfectly fitted packaging ensures that the customer will receive the products in great condition; hence, customer trust is enhanced.

Operational Efficiency: Accurate measurements cut down the packing time and also help in the stock control.

Rules & Regulations: A lot of carriers have very strict limitations concerning the size and weight of boxes.

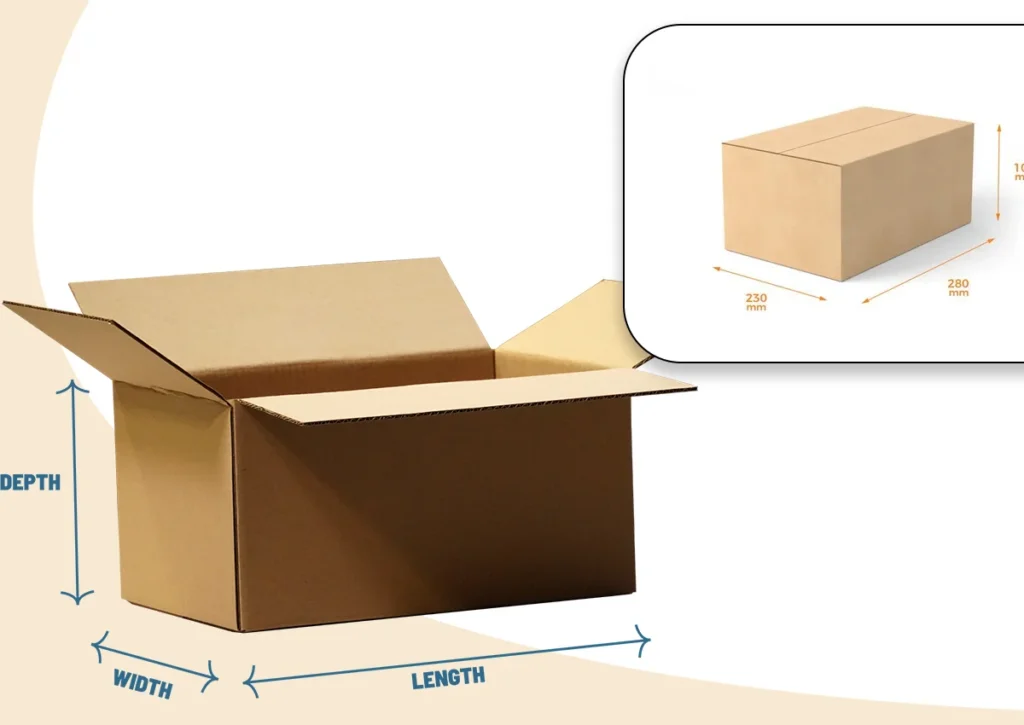

How to Measure a Shipping Carton Accurately

Accurate shipping carton dimensions are the cornerstone of successful packaging. Following these step-by-step guidelines will enable you to accurately measure your box’s dimensions:

1. Measure the Length

The length refers to the longest part of a shipping box. It’s a part where the flaps are folded.

To determine the length of a shipping box, measure straight across with either a tape measure or ruler from one end of the box to the other end, measuring along the longest side.

The dimensions should be taken and recorded in inches. In this way, you can get consistent and easily understood information regarding measurements.

For example, a box may have a typical length of 16 inches.

2. Measure The Width

The width is always the short side of a box when the box is positioned with its length and width.

You can find the width by turning the box at a 90-degree angle and measuring from one side to another across the short dimension.

The flaps on the width side are typically shorter.

For example, using this same box example, the width may be equal to 12 inches.

3. Measure The Height

Height is the distance from the base to the top of the box. To determine this, flaps should be closed tightly, then measured from the bottom of the box to the top, either inside or outside.

As with standard box shapes, height can also be seen as depth. A height measurement of 12 inches would illustrate this concept very well.

4. How To Calculate the Volume Of the Box?

How to find the volume of shipping cartons? To measure this, multiply the length, width, and height. You can estimate storage space and shipping costs using this.

Volume= LxWxH

5. Consider Internal Dimensions

Whether you have valuable products or fragile ones, many products need internal dimensions as well for proper fitting and cushioning. Thus, also measure the width, length, and height for incorporating foam inserts, padding materials, or other protection packaging.

Standard Shipping Box Sizes

To make your packaging process extra streamlined, here are the various standard box sizes, from small, medium, large, to extra-large options. Go with the right size. It ensures your goods are properly fit, preventing damage and movement.

Small Shipping Boxes

| Size | Suitable For | Examples |

| 6”x6”x6” | Lightweight, small items | Jewellery, small electronics, cosmetics |

| 8”x6”x4” | Compact electronics, cosmetics | Smartphone accessories, perfumes |

| 10”x7”x4” | Books, magazines | Paperback books, small gift sets |

Medium Shipping Boxes

| Size | Suitable For | Examples |

| 12”x9”x6” | Clothing, toys | T-shirts, small toys |

| 14”x10”x4” | Larger books, shoes | Sneakers, electronic gadgets |

| 16”x12”x8” | Household items | Small kitchen appliances, home decor |

Large Shipping Boxes

| Size | Suitable For | Examples |

| 18”x14”x12” | Retail products, heavier items | Small furniture parts, bulk clothing |

| 20”x16”x10” | Household goods | Bedding sets, multiple apparel items |

| 22”x18”x16” | Comforters, pillows | Bedding, cushions |

Extra-Large Shipping Boxes

| Size | Suitable For | Examples |

| 20”x20”x18” | Bulk household items | Large blankets, multiple boxes of products |

| 30”x20”x20” | Bulky retail items | Large equipment, furniture parts |

Which benefits do you obtain by using standard sizes? No waste, efficiently manage inventory, and get compatibility with shipping carriers’ needs.

Why Shipping Carton Thickness Matters

The box is determined by the size of the custom carton, but the thickness of the box material is also very important in protecting products. Examples of different types of cardboard materials and their level of protection are discussed here!

Standards Cardboard: This type of cardboard is suitable for small or lightweight items and provides the lowest level of protection.

Corrugated Cardboard: This type of cardboard consists of fluted or wavy layers that are sandwiched between two layers of liners. Corrugated cardboard has better strength and durability. Therefore, this type of cardboard is better suited to ship heavier and/or more delicate items.

Thicker Cardboard Materials: If you choose thicker cardboard materials, you can get the best crush, impact, and puncture resistance.

After choosing the thickness of the box, you can consider the weight and fragility of the product, as well as the length of the shipping distance. Thicker boxes will absorb more of the shock when the boxes are bumped or dropped, and therefore will provide the best level of protection during shipping.

Impacts of Incorrect Container Sizing

A careless measurement may lead to a whole range of problems taking place that would have a negative impact on both your company and your customers:

- Last-Minute Shipping: Different box sizes can cause delays in either the reordering or repacking process.

- Product Destruction: Incorrect box size and a shortage of protection may lead to products’ damage.

- Higher Shipping Surcharges: If you have large parcels, then the charges also be

- calculated depending on their weight.

- Increased Costs: Goodies and volume-based returns increase the cost.

- Poor Customer Experience: Poor customer experience like broken or late products make them unhappy and may leave a bad review.

Important Considerations Before Customising Your Shipping Cartons

Prior to the personalisation of shipping boxes, think about the product’s dimensions, form, and weight.

Correct measurement avoids problems related to size, while getting to know the product’s fragility helps to determine the padding and material to be used.

Moreover, odd shapes or heavy items require either special or strong packaging to guarantee safe transport and the non-occurrence of damage.

Wrapping-Up

To deliver products safely and affordably, it is crucial to measure and select the appropriate shipping carton dimensions correctly. Before selecting or creating a box, always consider the product’s shape, size, weight, and level of fragility. Moreover, it is a standard practice to make sure that the dimensions of the box are not too tight but at the same time snug, and the box material’s thickness is also like this, that is, not too tight but snug, so that they can together offer good protection during the shipping process.Use this guide to achieve operational efficiency and customer loyalty through a more efficient shipping process. Happy Shipping!

FAQ's

-

Why are accurate shipping carton dimensions so important?

Accurate measurements lead to proper product protection, minimised shipping costs, and no delays, and they also increase customer satisfaction as fewer products are damaged during shipping. -

What are the standard dimensions for shipping boxes?

Standard sizes vary from small ( 6”x6”x6” to extra-large (30”x20”x20”), making the whole packaging and shipping process more efficient. -

What kind of issues may occur if there is an incorrect box size?

Wrong sizes may cause product damage, shipping delays, higher surcharges, increased costs, and poor customer experiences due to late or damaged deliveries. -

Does the thickness of a box depend on the safety of the product?

Thickness provides damage resistance. This is more significant for heavy or delicate items because it guarantees safe transportation.